Rice-Born Company to Ease Solar-Panel Manufacturing Goes Public, Gives Back

By Mike Williams, Rice News staff – September 17, 2009 – The first publicly traded company to spring from Rice University technology is now taking stock in some of the best brains at Rice.

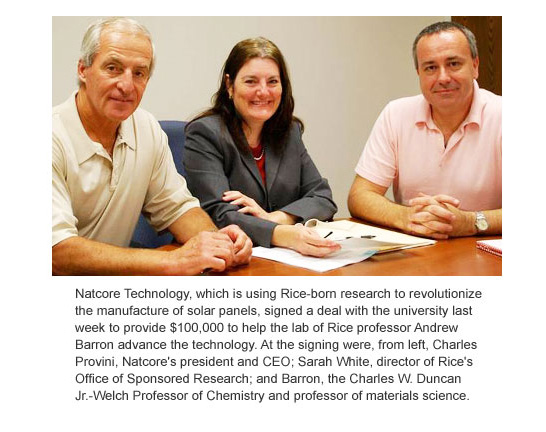

Natcore Technology, a New Jersey firm that specializes in advancing the science of solar energy, has signed an agreement to fund research by the Rice lab of Andrew Barron to the tune of $100,000/year. Natcore became the first Rice spinoff to go public when it was listed (as NXT.V) on the Canadian Stock Exchange. At publication time, shares were hovering at around 40 cents a share.

“Rice has licensed to public companies before, but this is the first Rice spinoff to go public,” said Barron, the university’s Charles W. Duncan Jr.-Welch Professor of Chemistry and professor of materials science, who co-founded the company and remains a technical consultant. “Other universities have been doing this kind of thing for years, but we never have,” he said.

“It’s an exciting step forward every time we get a product in the marketplace that we can attribute to Rice,” said Nila Bhakuni, director of Rice’s Office of Technology Transfer, who said Natcore’s “tremendous combination of money, savvy and talent” will raise the university’s research profile and the potential for revenue.

“It reflects well on Rice and on the work by our brilliant researchers and enhances our Vision for the Second Century,” she said. “Certainly Dr. Barron has a very impressive track record and a long history of entrepreneurship. He’s amazingly creative in his research activities.”

The company is based on technology invented by Barron’s lab and licensed from Rice called liquid phase deposition (LPD). The process deposits thin films of silicon dioxide and mixed silicon oxides onto solar panels and other products. Before LPD, putting critical antireflective coatings on solar cells involved huge vacuum furnaces operating at 1,800 degrees Fahrenheit. Barron’s technology makes the process easier and cheaper by coating the cells’ silicon wafers with a mild chemical bath at room temperature.

The high temperatures involved in making solar cells have required silicon panels thick enough to withstand the heat without warping. Eliminating the furnace means the silicon in solar cells can be as much as 60 percent thinner.

Natcore claims LPD will make the mass manufacture of tandem solar cells possible. Such cells have the potential to double the power output of today’s most efficient panels, the best of which now convert only about 20 percent of sunlight captured into electricity. The company expects to apply the technology in semiconductor and fiber optic applications as well.

Barron said the new research funding will help his lab advance the technology even further, increasing its efficiency while making the manufacture of solar cells more environmentally friendly. He also sees potential for LPD to be used in the manufacture of other materials, from sophisticated contact lenses to windows that serve double duty as transparent solar panels.

The company itself won’t make solar cells but rather equipment to add to manufacturers’ production lines. President and CEO Charles Provini is convinced manufacturers will quickly see the light when Natcore’s process allows them to shut down their furnaces and recycle chemicals, greatly reducing waste.

“We don’t think we have any competition,” said Provini, adding that a current glut in the supply of solar panels could present an opportunity for Barron’s technology.” Since solar panels are becoming more of a commodity, manufacturers are concerned about their profit margins. Our process can reduce their overall costs and increase their margins.”

Natcore Technology © All rights reserved. Sitemap ![]()

Comments are closed.